Unbreakable

Panoramic

Space-efficient

Child-safe

Affluent aesthetics

Low-cost

Eco-friendly

ELEVATE YOUR COMFORT TO A BETTER LIFESTYLE

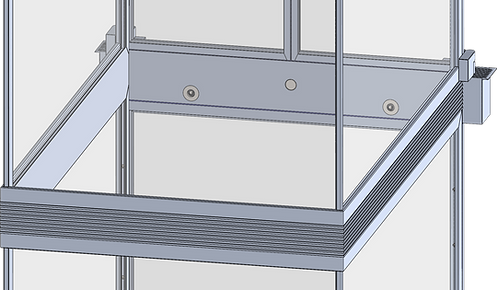

Construction. From the very beginning we abandoned traditional solutions that come with bulky elements, like concrete shaft, rails, guides, lifting cables, counterweights, pneumo-pins,

gears, pulleys, heavy metal structures and noisy mechanisms, i.e. we got rid of everything that does not relate to the meaning of “luxury" and "comfort”.

Introducing a revolutionary concept in elevator technology – use of tempered glass as a structural material. The main building blocks of AirLift are made of structural tempered glass and aviation aluminum.

Tempered glass panels of the Hoistway are running from floor-to-ceiling and providing a gorgeous, truly panoramic look. The Cabin too, is made of floor-to-ceiling translucent tempered glass with translucent ceiling and a sexy appeal.

Tempered glass - is the only structural material of the construction, which allows shrinking the overall footprint several times (!), and reducing metal parts to very thin frames, that are protecting the edges of glass panels.

Tempered glass is the only structural element of AirLift™

AirLift™ has 3-5 times smaller footprint for the same cabin space and load compared to other commercial solutions

Vacuum Technology. AirLift™ uses vacuum forces for setting the elevator cabin into a motion. AirLift™ elevator cars are smoothly gliding up and down a glass shaft, literally hovering in the air, supported by vacuum forces only, without visible means of support from top or bottom of the cabin. The elevator hoistway (shaft) – is an airtight vacuum chamber with elevator cabin acting similar to a piston in a syringe. When a vacuum compressor sucks the air from the top of hoistway, the air pressure above the cabin decreases, while the air pressure below the cabin remains atmospheric.

This air pressure difference above a critical threshold is pushing the cabin up, while below this threshold – allows the cabin to descend. Behind this simplicity stands precise mechanics and smart electronics that control optimal amount of vacuum needed for moving the cabin up and down or holding it steady at a given elevation with a variable load.

Docking mechanism allows the cabin to dock at the destination floor and stay docked during loading and unloading of the passengers.

Design. When it comes to installing a furniture or an appliance in a home, design should be one of the most important factors to consider.

The surface of the hoistway shaft has smooth surface for the vacuum seal to operate unimpeded. All the "stitches" between glass panels and floor belts present a uniform surface

AirLift™ has designed an ergonomically friendly solution that can fit into almost any interior, creating luxury and comfort for your living.

Bolt-less signature design exhibits no visible bolts or nuts of any kind, despite of thousand of bolts used in the construction

The entire structure of AirLift™ is made of clear tempered glass and can fit nicely into virtually any interior, bringing more light and openness into your environment. Floor-to-ceiling glass panels of the elevator, touchless buttons behind the cabin glass wall, illuminated cabin with hidden light sources, air purification with HEPA filters and UV light treatment, smooth, low noise – all meant to achieve high standards in luxury and comfort.

In addition to a luxury appeal, AirLift™ employs a bolt-less design style, which exhibits no visible bolts, nuts or fasteners of any kind, and giving Blissera products a unique signature design luxury outfit, yet all components of the system of both the Hoistway and the Cabin are fastened together using over a thousand of bolts hidden from a naked eye – thanks to our unique bolt-less signature design style.

The boltless design style is used across the entire system, both in the cabin, as well as in the elevator shaft.

Multitude of bolts, nuts and other fasteners hold the entire construction together, yet no fasteners of any kind are visible

from inside or outside of the hoistway or the cabin

AirLift's electronics system has been custom designed from ground-up to meet our stringent requirements for having full control over hundreds of sensors and dozens of motors and solenoids in the system. All sensors boards come with a CPU, memory and network connectivity interfacing a proprietary AirLift network of sensor devices and control mechanisms. Tens of thousands of small electronic components along with thousands of lines of computer code constitute the brain of AirLift that constantly scans all the devices of the system and remotely reports to the central server via a secured Internet link data about the "health" of the system.

Such automated diagnostics and reporting approach allows our tech support team to remotely detect failures in the systems and even react to warnings requiring maintenance or parts replacement, thus significantly reducing maintenance costs for our customers.

The remote diagnostics approach also allows to remotely upgrade the firmware of the system adding new and enhanced features as they become available.

Your AirLift team